Science

Innovation in Graphene: Sustainable Solutions for Advanced Materials

Graphene is gaining attention as a revolutionary material due to its remarkable properties, including strength, electrical conductivity, and thermal efficiency. Despite over a decade of research, many applications of graphene remain confined to laboratory settings. A major hurdle is the material’s poor solubility in common solvents, which necessitates complex and often environmentally harmful functionalization processes.

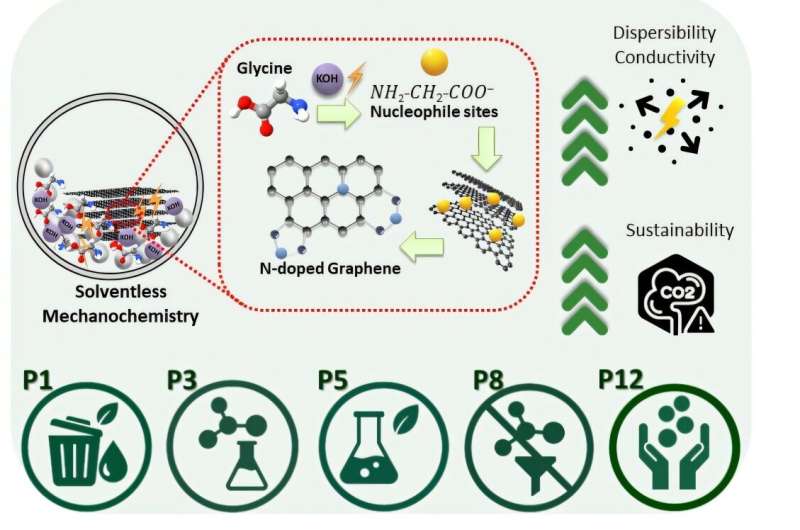

In a recent study published on December 25, 2025, in ACS Sustainable Chemistry & Engineering, a team of researchers led by Chamalki Madhusha at Monash University has proposed a more sustainable method for producing nitrogen-doped graphene nanoplatelets (N-GNPs). This innovative approach employs a solvent-free, bio-derived mechanochemical technique that could transform the production of functionalized graphene materials.

Challenges of Functionalizing Graphene

While pristine graphene boasts impressive characteristics, many advanced applications, such as smart coatings and self-healing polymers, require chemical modifications to enhance dispersion. One prevalent method is nitrogen doping, which modifies graphene’s electronic structure and improves its compatibility with solvents and polymer matrices.

Traditional nitrogen-doping methods, however, present significant challenges. They often involve toxic nitrogen precursors, rigorous purification processes, high-temperature post-annealing (over 600 °C), and generate considerable chemical waste. The environmental impact of these processes raises serious questions, particularly as the demand for sustainable materials grows.

Mechanochemistry: A Green Alternative

To address these issues, the research team explored mechanochemistry, a technique using mechanical forces to drive chemical reactions without solvents. This method, recognized for its potential in green chemistry, can significantly reduce energy consumption and simplify the production process.

By employing a ball-milling technique, the researchers functionalized graphite using a bio-derived nitrogen source (amino acids) at ambient conditions. This innovative approach produced N-GNPs without solvents or toxic reagents, while maintaining high electrical conductivity and good dispersibility—two critical challenges in graphene processing.

The evaluation of sustainability was a key aspect of the study. The team assessed not only the performance of the resulting material but also the environmental impact of its production. They measured waste generation through the E-factor metric, a standard in green chemistry, and found that their method achieved a high material yield of around 80%, with a significantly lower environmental footprint compared to conventional functionalization strategies.

Importantly, by eliminating solvents and post-annealing steps, the overall energy consumption of the process was markedly reduced. This demonstrates how thoughtful process design can enhance the sustainability of advanced materials while still delivering high-quality products.

The incorporation of nitrogen into the graphene lattice modifies electron movement, resulting in improved electrical conductivity and enhanced chemical reactivity. The N-GNPs produced in this study retained their structural integrity while benefiting from the functional enhancements provided by nitrogen doping. When used as nanofillers, N-GNPs exhibited strong potential to improve the electrical, thermal, and mechanical properties of composite materials.

The implications of this research extend beyond graphene itself. By rethinking traditional production methods, the study advocates for a broader shift towards sustainable practices in advanced materials manufacturing. In industries such as electronics, aerospace, and energy storage, these considerations are becoming increasingly crucial for compliance with environmental regulations and cost management.

Looking forward, the research team aims to adapt this green synthesis approach for other dopants and composite systems, paving the way for scalable manufacturing of sustainable advanced materials. As the demand for functional materials continues to rise, the integration of environmentally friendly practices will be essential to shaping the future of material science.

This study underscores the importance of aligning nanomaterial innovation with sustainability goals. By demonstrating that environmentally responsible methods can deliver high-performing materials, the researchers open new pathways for the creation of advanced composites that are both efficient and sustainable.

-

Science2 months ago

Science2 months agoUniversity of Hawaiʻi at Mānoa Joins $25.6M AI Initiative for Disaster Monitoring

-

Health2 months ago

Health2 months agoNew Gel Offers Hope for Regrowing Tooth Enamel in Dentistry

-

Science1 month ago

Science1 month agoALMA Discovers Companion Orbiting Red Giant Star π 1 Gruis

-

Lifestyle1 month ago

Lifestyle1 month agoPark Jung Min’s Endearing Moment with Hwasa Steals Show at Awards

-

Science2 months ago

Science2 months agoIROS 2025 to Showcase Cutting-Edge Robotics Innovations in China

-

Lifestyle2 months ago

Lifestyle2 months agoStone Island’s Logo Worn by Extremists Sparks Brand Dilemma

-

Lifestyle2 months ago

Lifestyle2 months agoSampson County Celebrates Susie Faison’s 100th Birthday Milestone

-

Health2 months ago

Health2 months agoStartup Liberate Bio Secures $31 Million for Next-Gen Therapies

-

Lifestyle2 months ago

Lifestyle2 months agoMary Morgan Jackson Crowned Little Miss National Peanut Festival 2025

-

Health2 months ago

Health2 months agoTop Hyaluronic Acid Serums for Radiant Skin in 2025

-

Science2 months ago

Science2 months agoArizona State University Transforms Programming Education Approach

-

Politics2 months ago

Politics2 months agoJudge Considers Dismissal of Chelsea Housing Case Citing AI Flaws